Brick Laying Robot[:]

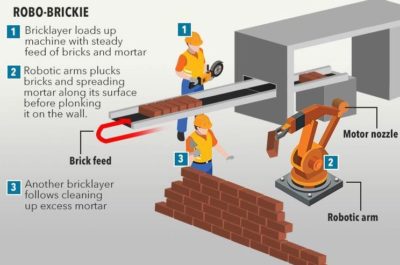

Auburn University is constructing the Jay and Susie Gogue Performing Arts Center, and is incorporating some new and innovative help. Construction Robotics’ SAM100, which is short for Semi-Automated Mason, is being used throughout the project to help lay bricks. The robot is capable of placing more than 3,000 bricks per day, and is the first commercially available robot for onsite masonry construction. The machine utilizes a conveyor belt and a robotic arm to do its job, which effectively makes the repetitive task of laying bricks obsolete for workers equipped with the SAM100; instead, workers are responsible for reloading bricks into the machine and to clean around the bricks that are placed by SAM. The robot allows you to program the design pattern of the mason work that needs to be completed as well, which significantly reduces the burden on construction foreman to ensure that designs are followed precisely.

“The robotic device can reportedly place 3,000 bricks per day, and while it still requires some human oversight, SAM reduces manpower requirements by at least four or five masons and allows the company to better utilize its resources.”

Source[:]

![Brick Laying Robot[:] Brick Laying Robot[:]](https://www.ccinnovations.ca/wp-content/uploads/2018/07/2017.03.27-SAM-2-150x150.jpg)

Follow

Follow

![Brick Laying Robot[:] Brick Laying Robot[:]](https://www.ccinnovations.ca/wp-content/uploads/2018/07/2017.03.27-SAM-2-1-150x150.jpg)